Injection Mold Tooling Capabilities

We specialize in the design and fabrication of precise custom injection molds using top-quality materials. Our processes guarantee exceptional consistency and repeatability, with quick turnaround times and competitive prices. All the plastic injection molds we produce conform to international standards. Whether it’s a one-off project, small production runs, or full-scale production tooling, we deliver durable and dependable mold tools.

| Mold Class | Purpose | Shot Life | Tolerance | Cost | Lead Time |

| Class 105 | Prototype Testing | Under 500 cycles | ± 0.02mm | $1000 + | 7-10 days |

| Class 104 | Low-volume Production | 1.000 - 10,000 cycles | ± 0.02mm | $10,000 + | 20+ days |

| Class 103 | Low-volume Production | 10,000 - 100,000 cycles | ± 0.02mm | $15,000 + | 30+ days |

| Class 102 | Medium-volume Production | 100,000 - 250,000 cycles | ± 0.02mm | $30,000 + | 30+ days |

| Class 101 | High-volume Production | 250,000 - 1,000,000 cycles | ± 0.02mm | $50,000 + | 45+ days |

Continuous Production | 1,000,000+ cycles | ± 0.02mm | $75,000 + | 60+ days |

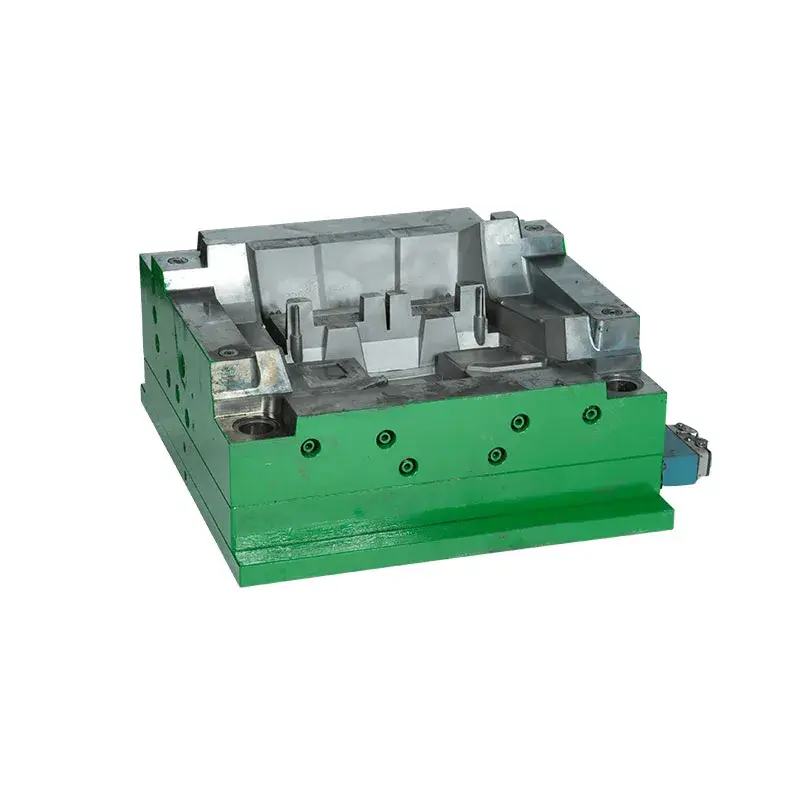

Varieties of Plastic Injection Molds

We provide a range of injection mold tooling options tailored to your specific requirements and applications. Whether you need prototype mold tooling, production molds, or export molds, Scojet is your trusted partner.

Single Cavity Mold

Achieve efficient production of low-volume plastic parts using our top-notch single cavity injection molds. These cost-effective mold tooling solutions offer greater control over the plastic manufacturing process.

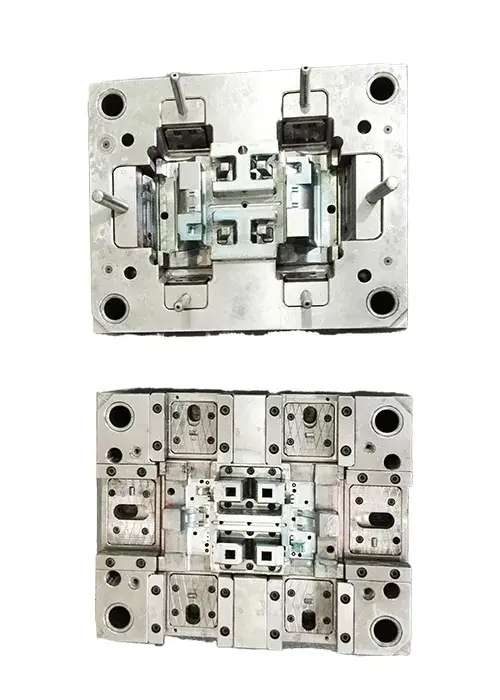

Multi Cavity Mold

Streamline the production of multiple plastic molded parts with our high-quality multi-cavity molds. Our multi-cavity injection molds not only optimize cycle times but also reduce the cost per unit part. With increased productivity, you can obtain larger quantities of parts in each cycle.

Stack Mold

Boost the production output of your injection molding process with our cutting-edge stack molds. Scojet provides top-notch stack mold tooling to enhance your molding efficiency and lower overall part costs. We can design stack molds with an equal or varying number of cavities on each parting surface, allowing you to create multi-component assemblies in a single cycle.

2K Injection Mold

An affordable and effective custom injection molding solution for molding two distinct plastic materials. We offer 2K injection mold tooling, enabling the seamless integration of soft and hard plastics into a single product. This approach not only allows for cost savings but also consolidates assembly steps within a single molding process.

Our Injection Mold Tooling Services for Diverse Industries

For more than a decade, Scojet has been the preferred choice in various industries, including automotive, agricultural, construction, outdoor power equipment, powersports, medical, and food service, offering cost-effective and dependable injection mold tooling services.